Blakeney lime kiln situated near Blakeney in the Forest of Dean

Before during and after shots of conservation works for Forestry England

Bishop Hooper Monument

The monument was cleaned using the thermatech system , a series of mortar repairs and pointing to bring back some uniformity and then sheltercoated in a warm Bath stone coloured mix.

Trafalgar Colliery works to the chimney base

This is the chimney base to allow the draw out of gases from the mine shaft,,a tunnel runs approx. 250metres from the mine shaft to the chimney,a fire would be lit and this in turn would suck the gases from the shaft up through the chimney .From ground level to the bottom of the chimney is approx. 3m and the tunnel is 1.2m wide and 1.8m high. the photos go through the stages of the works.

St George’s church Kings Stanley

This is high level lime Pointing to St George’s church Kings Stanley.

Bathurst graffiti removal

This is a before and after of graffiti removal to the inside of the hexagon Bathurst estate again using the Thermatech steam cleaner

Winston Churchills

Winston Churchills grave before and after being cleaned with a Thermatech steam cleaner.

Brimstone farm (National Trust)

Re-pointed in hydraulic lime mortar cattle briars Brimstone farm (National Trust)

The Old Rectory France lynch

Cleaning ,Pointing and stone repairs

Flint work Marlborough college

Before , during construction and finished

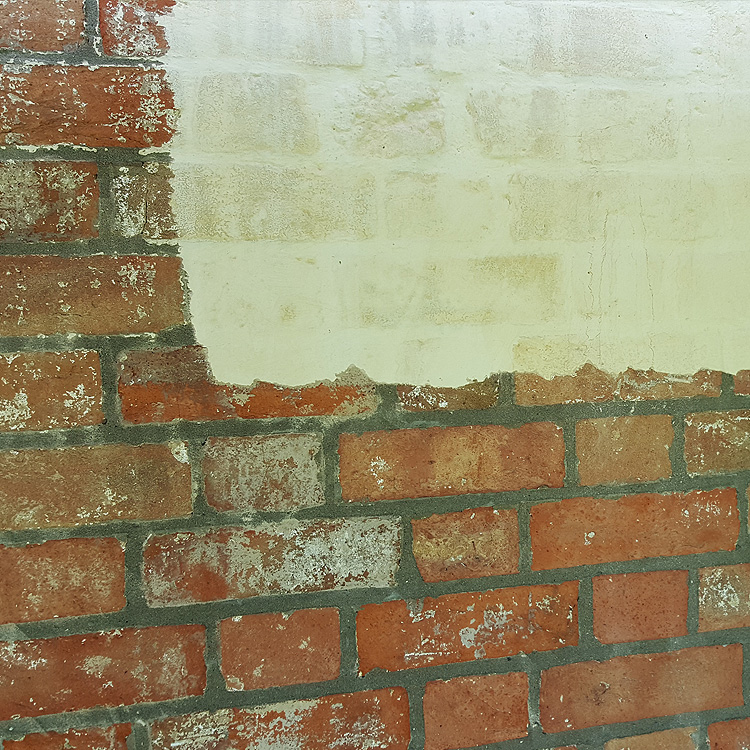

Whitminster

Commissioned to remove old paint work off building. Using Thermatach technology we cleaned and restored the building back to its original stone.

St Pierre Marriott Hotel

The chimney which had become approximately 100mm out of upright in 4 metres and also very unsteady due to iron cramps swelling inside the joints.

The chimney was taken down by 14 courses and rebuilt using 75% new stone in the ashlar coursing and 100% from the plinth to the top.

Beer Mausoleum Highgate Cemetery

Raking out loose and open roof joints using an oscillating grinder due to the thinness of the joints. Internal conservation of the occulus and rib stones and removal of algae stains. Replacement of one of the perspex windows to perspex louvres to allow additional ventilation in the top of the mausoleum.

Egyptian Avenue and Outer Circle Highgate Cemetery

Refixing of cementious stucco by pinning,grouting and sticking with a P.F.A and hydraulic lime mix. Filling of cracks and fissures and replacement of lost stucco panels. On two of the catacomb doorways new phosphorous bronze threshold strips were introduced to stop water ingress in heavy rain.

Oxwick Farm

General Repairs to the external fabric including brick replacement,stone rebuild,window replacement and pointing.

Internally Plastering and timber repairs.

Kensington Roof Gardens

Cleaning of the Tudor walkway Arches

The arches made up of a sand and cement based mortar cast in sections to make up jamb and head pieces,with some decorative mouldings and finishes made pproximately 75 years ago.

The cleaning process started with steam cleaning using the Thermatech machine to get rid of surface deposits and to soften up sulphation and barbeque smoke residue, heavy depositing was then rubbed back and opened up to allow a 10% ammonia poultice to be applied . After leaving this on for an evening the poultice was then removed and the residue washed away using the Thermatech and scrubbed down using lamb chop stainless steel brushes and then a final washdown.

Any stubborn areas of dirt that were not removed in the first stages, a second poultice was applied and the cleaning process was repeated.